Cutting-edge Fasteners and Machining Solutions for Complicated Designs

Cutting-edge Fasteners and Machining Solutions for Complicated Designs

Blog Article

Navigating the Globe of Fasteners and Machining: Strategies for Precision and Speed

In the complex world of bolts and machining, the quest for precision and speed is a perpetual difficulty that demands careful interest to detail and calculated preparation. From comprehending the diverse range of fastener types to selecting optimal products that can withstand strenuous needs, each action in the procedure plays an essential duty in attaining the wanted end result.

Understanding Fastener Types

When selecting fasteners for a job, recognizing the various kinds offered is crucial for guaranteeing optimum performance and dependability. Screws are used with nuts to hold materials with each other, while screws are versatile fasteners that can be used with or without a nut, depending on the application. Washers are essential for dispersing the lots of the fastener and stopping damages to the product being fastened.

Choosing the Right Materials

Understanding the value of choosing the ideal materials is critical in ensuring the optimal efficiency and dependability of the picked bolt kinds reviewed previously. When it involves bolts and machining applications, the product selection plays a vital duty in determining the overall strength, sturdiness, deterioration resistance, and compatibility with the designated atmosphere. Different products use varying properties that can considerably influence the performance of the fasteners.

Common products made use of for bolts include steel, stainless steel, brass, titanium, and aluminum, each having its distinct toughness and weak points. Steel is renowned for its high stamina and durability, making it appropriate for a broad array of applications. Selecting the ideal product entails thinking about aspects such as toughness demands, ecological conditions, and spending plan restrictions to make sure the wanted performance and durability of the bolts.

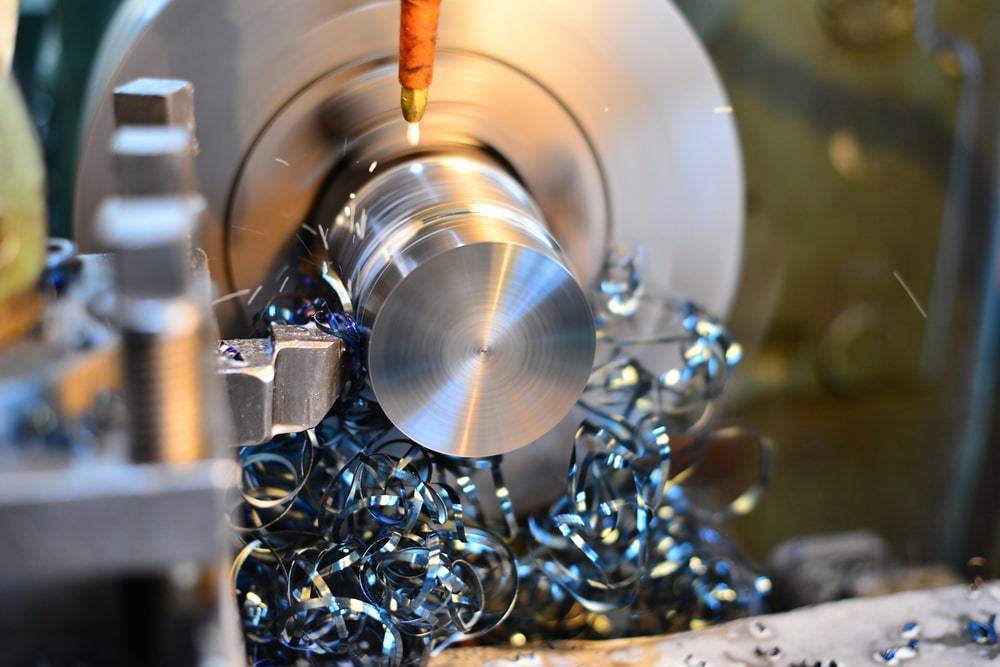

Precision Machining Techniques

Along with CNC machining, various other accuracy strategies like grinding, transforming, milling, and boring play crucial functions in bolt production. Grinding assists accomplish fine surface coatings and limited dimensional tolerances, while transforming is typically made use of to create round components with specific diameters. Milling and exploration procedures are essential for forming and developing openings in fasteners, ensuring they satisfy precise specs and feature properly.

Enhancing Speed and Performance

To enhance bolt production procedures, it is vital to simplify operations and implement effective strategies that complement accuracy machining methods. One vital strategy for improving speed and effectiveness is the application of lean manufacturing concepts. By minimizing waste and concentrating on continual enhancement, lean practices assist get rid of traffic jams and optimize workflow. Furthermore, buying automation innovations can substantially enhance production rate. Automated systems can deal with repeated jobs with precision and rate, permitting employees to focus on even more complex and value-added tasks. Adopting Just-In-Time (JIT) stock management can likewise improve effectiveness by guaranteeing that the ideal products are readily available at the ideal time, lessening excess supply and minimizing preparations. Promoting a society of collaboration and communication among group members can improve general effectiveness by promoting openness, problem-solving, and development. By integrating these approaches, suppliers can attain an equilibrium between speed and precision, eventually enhancing their competitive side in the fastener industry. my website

Quality Assurance Actions

Carrying out extensive quality assurance measures is vital in guaranteeing the dependability and consistency of bolt items in the manufacturing procedure. Quality control procedures incorporate numerous phases, beginning with the choice of resources to the last evaluation of the ended up fasteners. One essential aspect of quality assurance is performing thorough material examinations to confirm compliance with specifications. This includes assessing elements such as product structure, toughness, and toughness to assure that the fasteners meet industry requirements. Additionally, monitoring the machining processes is vital to support dimensional accuracy and surface finish top quality. Using innovative technology, such as automated inspection systems and precision measuring devices, can enhance the precision and efficiency of quality assurance procedures. click this link

Regular calibration of tools and machinery is necessary to maintain uniformity in manufacturing and make sure that fasteners meet the required tolerances. Implementing strict procedures for identifying and addressing flaws or non-conformities is crucial in stopping substandard products from entering the marketplace. By developing an extensive quality control structure, makers can copyright the reputation of their brand name and supply fasteners that fulfill the greatest criteria of efficiency and toughness.

Final Thought

In the elaborate realm of fasteners and machining, the quest for accuracy and rate is a perpetual challenge that demands careful focus to information and strategic preparation. When it comes to fasteners and machining applications, the product selection plays an essential function in figuring out the total toughness, durability, deterioration Home Page resistance, and compatibility with the designated atmosphere. Precision machining includes numerous sophisticated approaches that make sure the tight tolerances and specifications required for fasteners.In addition to CNC machining, other precision strategies like grinding, turning, milling, and drilling play vital functions in bolt manufacturing.To maximize fastener production processes, it is necessary to improve procedures and execute effective methods that enhance precision machining strategies.

Report this page